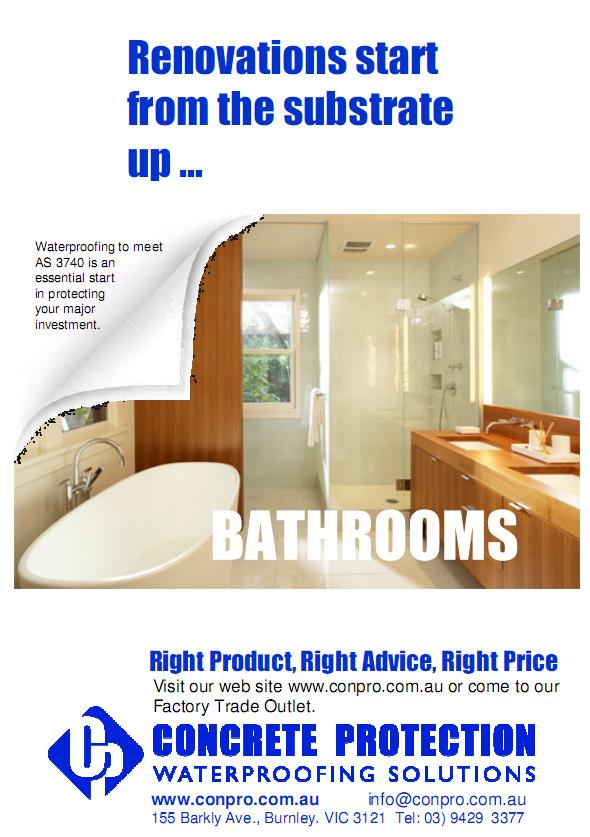

Bathrooms, laundries, and sanitary rooms are the wettest areas in a house, and improper waterproofing can lead to significant structural damage. On average, bathrooms are renovated every 10 years, making them one of the most frequently updated rooms in a home. Fortunately, the Australian Standards AS 3740 (2021) provide a “Deemed-to-Satisfy” (D-t-S) solution for waterproofing compliance under the National Construction Code (NCC 2022). The updated NCC now includes two D-t-S compliance options: the AS 3740 standard and the ABCB Housing Provision Standard 2022.

Both application and membrane products should comply with Australian Standards. The following information is designed for practical advice:

NEW CONSTRUCTION

Building code compliance refers to the National Construction Code (NCC 2022) objectives with either Deemed-to-Satisfy Solutions (Australian Standard AS3740: 2021) and ACBC Housing Provisions Standard 2022 or a Performance Solution authorized by the Registered Building Surveyor (under State legislation).

Both NCC Volume 1 & 2 have the same reference with details explained in AS3740. The Bathroom requirements include substrate conditions and cover options of design including; Showers with hobs, Hobless Showers (walk in), Bath Showers and Disables Showers the former two are most popular.

VBA have some useful reference documents and videos on their website.

VBA Practitioner-Education-Series-_Waterproofing-of-Wet-Areas-webinar- May 23

VBA-Fact-Sheet-Waterproofing-of-Wet-Areas -April 23

A major change in the for the industry to be aware of in AS3740:2021 occurs in Appendix E with reference for a product Compatibility Chain of proof.

Showers with Hob

AS3740: 2021 4.7 Hob Construction

There are minor variations in the new Standard to review.

AS 3740: 2010 3.13.3 Hob Construction (Showers)

This clause nominates that the substrate for hobs must be constructed from masonry, concrete, corrosion-resistant metal or similar material. Autoclaved aerated concrete may be used for internal membrane systems, but not for external membrane systems. When autoclaved aerated concrete are used, priming the surface is required prior to membrane application. All gaps, joints and intersections of the hob substrate are to be made flush before membrane application. The hobs must be adequately secured to the floor, plus sealed to the wall prior to internal membrane application.

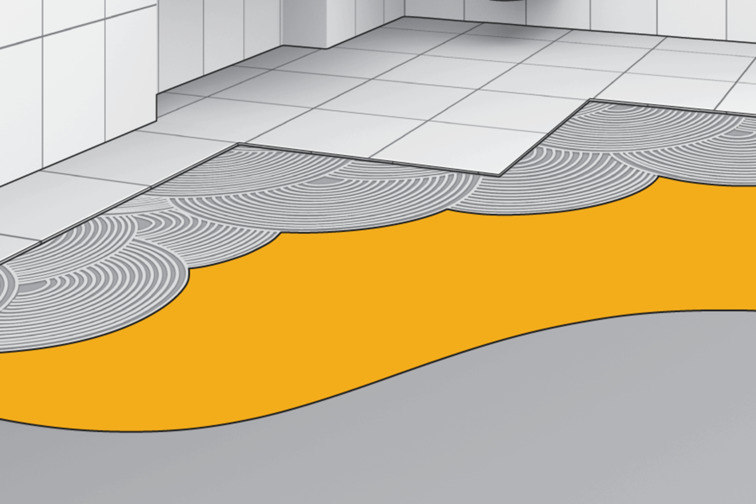

Start with the substrate and assess the condition of the slab or timber sheeting to check for any trapped moisture. If there’s any uncertainty, apply a vapour barrier coating as a precaution. When planning the project, account for potential building movement by ensuring all wall/floor joints, drains, hobs, sheet joints, and movement joints are properly secured. For the Australian climate, we recommend using liquid-applied membrane systems, as they are both practical and cost-effective for achieving a reliable result.

BATHROOM INSTRUCTIONS – Waterproofing Showers with Hob

Hobless Showers

AS 3740: 2021 4.15.3 Showers without hobs or step-downs

The new Standard has expanded descriptions.

AS 3740: 2010 3.13.5 Unenclosed Showers

This Clause sets out requirements for two types of unenclosed showers, as follows.

- Type 1; unenclosed shower has a device that will restrict splashing during use. A waterstop shall be placed under the device and across the opening of the shower screen.

- Type 2; unenclosed shower which does not have a device that will restrict splashing (as with people with disabilities). The water stop shall be a distance of a minimum of 1500mm from the wall connection of the shower rose.

AS3740: 2021 also has greater definition of Vinyl and concrete floors.

BATHROOM INSTRUCTIONS – Waterproofing Hobless Showers

Key Products:

- Sikaflex PRO – polyurethane

- SIKAFLEX -11 FC -2019

- Polycloth – reinforcing fabric

- Fibreglass Matting

- MICROL – Heavy Duty Waterproofing Membrane

- FIBREFLEX – Internal Waterproofing Membrane

- Sika-tite WPU 2019

- Sikalastic-1K-pds

- Mapelastic Smart brochure

YouTube video – Bond Breaker System – Class II Membranes

SHOWER REPAIRS

For both hob and step-down showers, if leaks are a significant issue, treat the project as a new construction: remove the existing shower and rebuild. For minor repairs, remove any silicone and reseal the joints using polyurethane. To minimize water penetration, apply a water repellent over the tile grout lines and tiles, and ensure the exit drain is properly waterproofed. In more severe cases, cover the tiles with a trafficable polyurethane floor coating.

Key Products:

- Tile and Grout Sealer – solvent water repellent

- Sikaflex PRO – polyurethane

- Sikafloor_-14_Prep n Prime

- Sikalastic-moistureseal

- Sika-tite WPU 2019

- SIKALASTIC -1 K – 2019

- Contec FLEX Kit Brochure 2021

- Mapelastic Smart brochure

- Eco Prime Grip – Mapei

Reference information:

Diagrams care of MBA NSW and other sources (jpeg diagrams)

Youtube video – Bond Breaker System- Class II Membranes